QuarterTurn

In this example, we will estimate the rise in temperature due to Joules losses in a stranded conductor. An electrical potential \(V_0\) is applied to the entry/exit of the conductor which is also cooled by a force flow.

The geometry of the conductor is choosen as to have an analytical expression for the temperature.

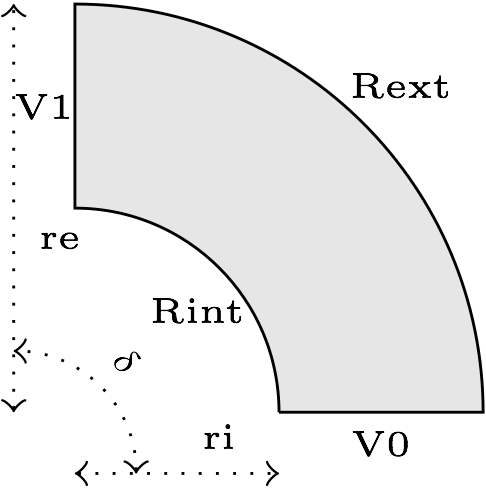

1. Geometry

The conductor consists in a rectangular cross section torus which is somehow "cut" to allow for applying electrical potential. The conductor is cooled with a force flow along its cylindrical faces.+

In 2D, the geometry is as follow:

In 3D, this is the same geometry, but extruded along the z axis.

2. Input parameters

| Name | Description | Value | Unit | |

|---|---|---|---|---|

\(r_i\) |

internal radius |

30.6 |

\(mm\) |

|

\(r_e\) |

external radius |

53.2 |

\(mm\) |

|

\(h\) |

heigth |

2.305 |

\(mm\) |

|

\(\delta\) |

angle |

\(\pi/2\) |

\(rad\) |

|

\(V_D\) |

electrical potential |

0.125 |

\(V\) |

|

\(h_i\) |

internal transfer coefficient |

\(80e3\) |

\(W\cdot mm^{-2}\cdot K^{-1}\) |

|

\(T_{wi}\) |

internal water temperature |

303 |

\(K\) |

|

\(h_e\) |

external transfer coefficient |

\(80e3\) |

\(W\cdot mm^{-2}\cdot K^{-1}\) |

|

\(T_{we}\) |

external water temperature |

293 |

\(K\) |

|

As the mesh is, by default in mm, we use specific units for this tests. |

2.1. Model & Toolbox

-

This problem is fully described by a Thermo-Electric model, namely a poisson equation for the electrical potential \(V\) and a standard heat equation for the temperature field \(T\) with Joules losses as a source term.

2.2. Materials

| Name | Description | Marker | Value | Unit | |

|---|---|---|---|---|---|

\(\sigma\) |

electric conductivity |

omega |

\(58.e3\) |

\(S.mm^{-1}\) |

2.3. Boundary conditions

The boundary conditions for the electrical probleme are introduced as simple Dirichlet boundary conditions for the electric potential on the entry/exit of the conductor. For the remaining faces, as no current is flowing througth these faces, we add Homogeneous Neumann conditions.

| Marker | Type | Value | |

|---|---|---|---|

V0 |

Dirichlet |

0 |

|

V1 |

Dirichlet |

0.5/4. |

|

Rint, Rext, top*, bottom* |

Neumann |

0 |

As for the heat equation, the forced water cooling is modeled by robin boundary condition with \(Tw\) the temperature of the coolant and \(h\) an heat exchange coefficient.

| Marker | Type | Value | |

|---|---|---|---|

Rint |

Robin |

\(h_i(T-T_{wi})\) |

|

Rext |

Robin |

\(h_e(T-T_{we})\) |

|

V0, V1, top*, bottom* |

Neumann |

0 |

*: only in 3D

3. Outputs

| hsize | \(T_{min} (K)\) | \(T_{max} (K)\) | |

|---|---|---|---|

1 |

318.812 |

362.227 |

To change the mesh size hsize just edit the cfg file and change the corresponding line:

dim=3

units=mm

geofile=quarter-turn3D.geo

geofile-path=$cfgdir

...

[gmsh]

filename=$cfgdir/quarter-turn3D.geo

hsize=14. Reference

For more advanced results, including convergence rate of the error, see the test case from Feel++ Thermo-Electric toolbox.